Acrylic Scripting by Capability

CNC Routing

Precision-cutting of flat plastic sheets into custom shapes and profiles with tight tolerances — ideal for retail displays, components, and signage.

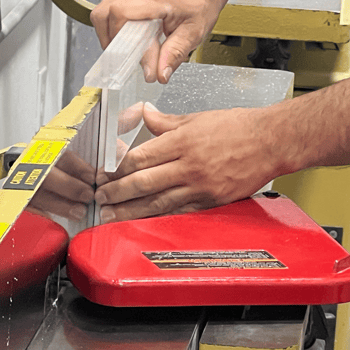

CNC Panel Saw Cutting

High-speed, high-accuracy cutting of large plastic panels into exact dimensions for further fabrication or assembly.

Flame Polishing

Creates crystal-clear, glossy edges on acrylic and other plastics — perfect for premium display applications and high-visibility parts.

Edge Finishing

We offer a range of edge treatments including sanding, buffing, and mechanical polishing to achieve smooth, safe, and aesthetic finishes.

Jointing

Precise fabrication of mitered, rabbeted, and butt joints to create strong, seamless connections between acrylic components.

Laser Cutting

Ultra-clean cuts with laser precision — perfect for detailed designs, tight tolerances, and polished edges in one pass.

Laser Etching

High-resolution, permanent marking and branding on acrylic surfaces for logos, part numbers, or decorative accents.

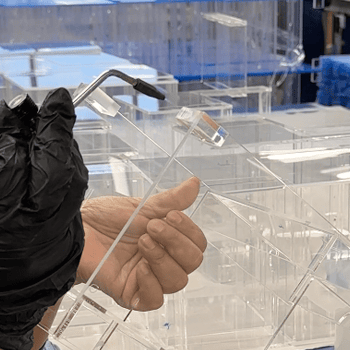

Gluing & Solvent Bonding

We use UV bonding, solvent welding, and pressure adhesives to create strong, clean, and often invisible joints for structural and display assemblies.

Heat Bending & Thermoforming

Forms flat plastic sheets into 3D shapes with heat — enabling curved displays, trays, brackets, and protective shields.

Drape Forming

Gravity-based thermal forming that shapes heated plastic over custom molds — ideal for smooth curves and complex contours.

Assembly

Precise, high-quality assembly of acrylic components — including bonding, fastening, and hardware integration — ensuring parts are production-ready or display-ready right off the line.

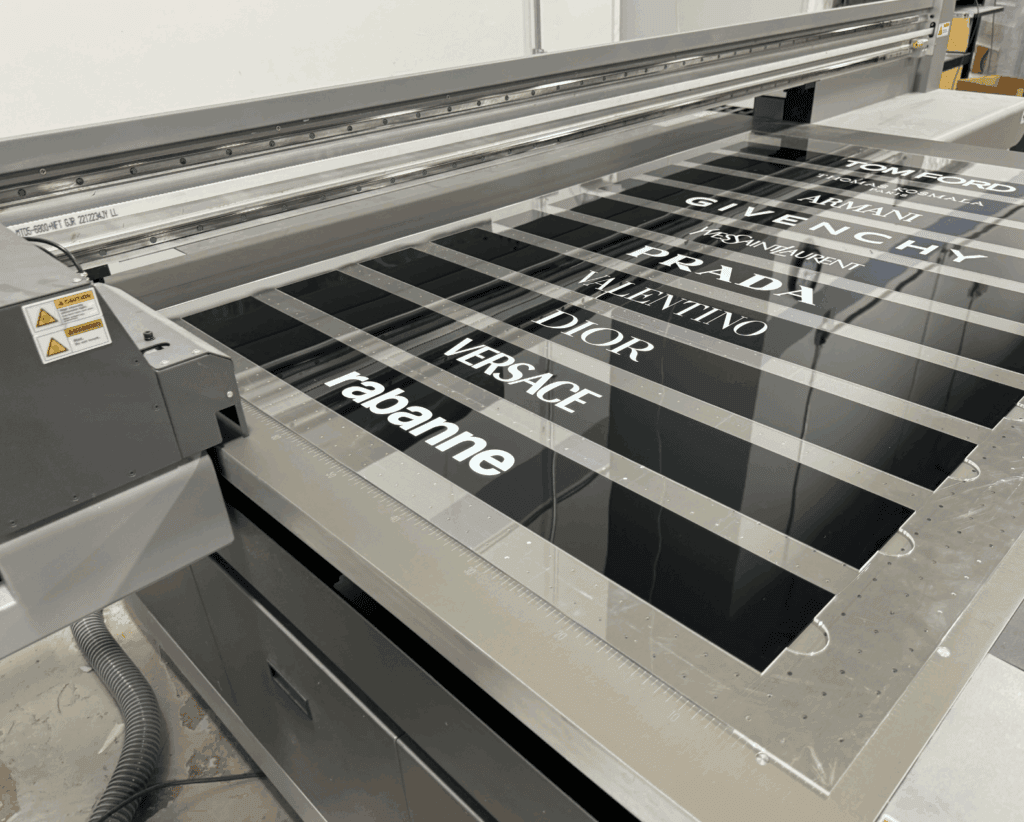

Direct-to-Substrate Printing

Full-color, high-resolution printing applied directly to acrylic and plastic surfaces — perfect for branded graphics, signage, and decorative elements.